Submission:

Submission:

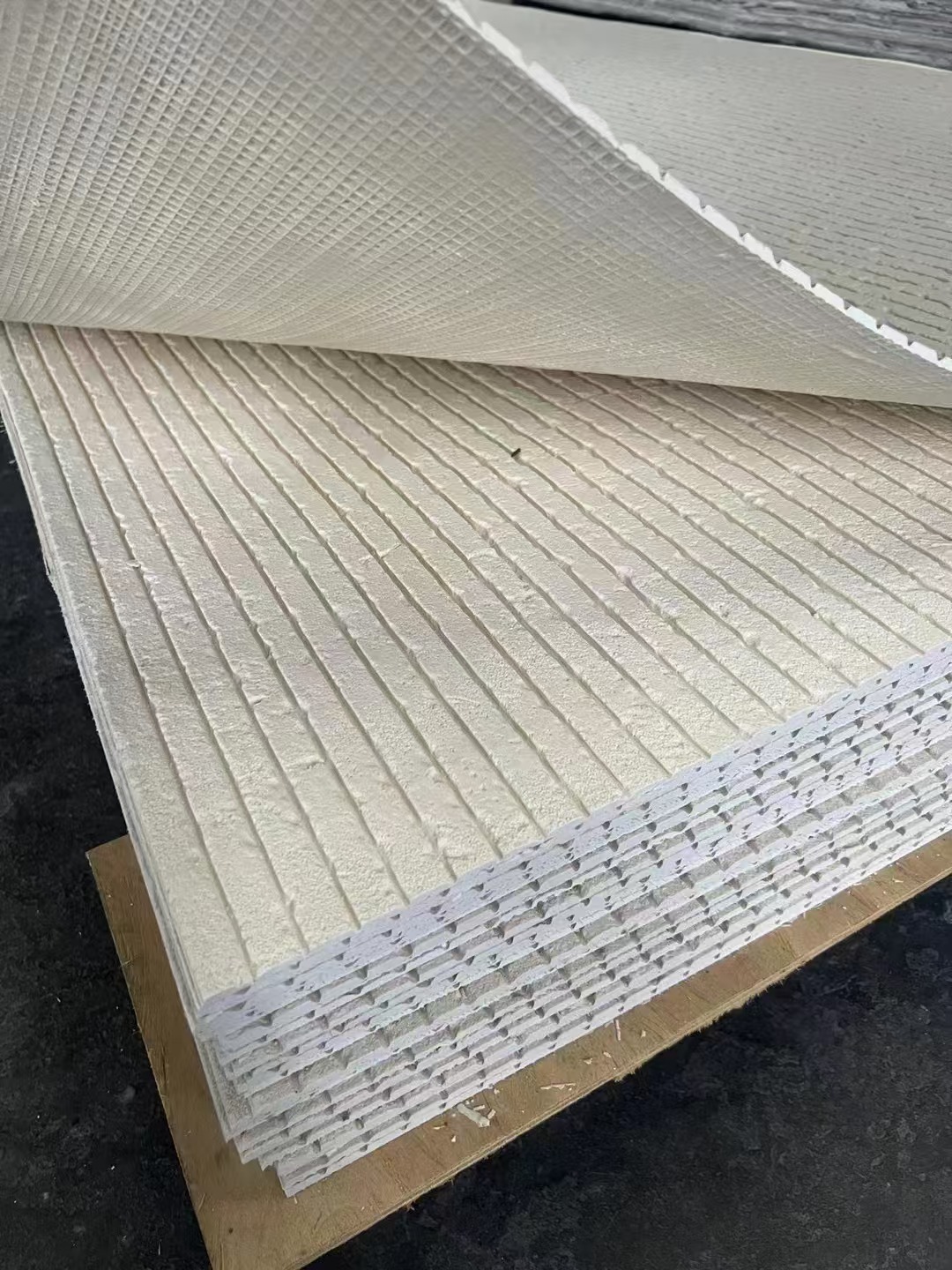

Key Features of Flexible Stone:

-

Natural Aesthetic: Retains the authentic look and texture of natural stone.

-

Lightweight: Much lighter than traditional stone, making it easier to handle and install.

-

Flexibility: Can be bent and curved to fit around corners and irregular surfaces.

-

Durability: Resistant to cracking, chipping, and wear.

-

Easy Installation: Can be cut with standard tools and adhered with strong adhesives.

-

Low Maintenance: Easy to clean and maintain.

-

Eco-Friendly: Often made from natural stone with minimal processing.

Applications in Interior Wall Decoration:

-

Feature Walls: Create stunning focal points in living rooms, bedrooms, or entryways.

-

Accent Walls: Add texture and depth to specific areas like behind TVs, fireplaces, or headboards.

-

Bathrooms: Use in shower areas or as backsplashes for a luxurious, spa-like feel.

-

Kitchens: Ideal for backsplashes or as a decorative element on kitchen islands.

-

Commercial Spaces: Enhance the interior of offices, hotels, restaurants, and retail stores.

-

Curved Surfaces: Perfect for wrapping around columns, arches, or other curved architectural elements.

Advantages of Using Flexible Stone:

-

Versatility: Suitable for a wide range of interior applications.

-

Aesthetic Appeal: Offers the timeless beauty of natural stone.

-

Cost-Effective: More affordable than traditional stone slabs.

-

Ease of Installation: Can be installed quickly and with minimal mess.

-

Customization: Available in various colors, patterns, and finishes to match any design style.

Installation Tips:

-

Surface Preparation: Ensure the wall surface is clean, dry, and smooth.

-

Adhesive Application: Use a high-quality adhesive suitable for flexible stone.

-

Cutting and Fitting: Measure and cut the flexible stone to fit the desired area.

-

Installation: Apply the adhesive to the back of the flexible stone and press it firmly onto the wall.

-

Finishing Touches: Seal the edges and joints for a polished look.

Maintenance:

-

Cleaning: Use a soft cloth or sponge with mild soap and water to clean the surface.

-

Sealing: Depending on the type of flexible stone, periodic sealing may be required to maintain its appearance and durability.

Flexible stone Interior wall decoration

Shandong Zeen Decoration Material Co., Ltd. , https://www.zeendecor.com